The Machinery’s Handbook is a comprehensive resource for metalworking‚ engineering‚ and manufacturing‚ offering detailed formulas‚ standards‚ and practical applications. Published by Industrial Press‚ Inc.‚ the 31st edition spans 2996 pages‚ available in PDF‚ ePub‚ and MOBI formats‚ making it a must-have tool for professionals and students alike. Its evolution over a century has solidified its authority in the field‚ providing indispensable guidance for design‚ manufacturing‚ and related disciplines. The digital edition enhances accessibility‚ ensuring it remains a vital reference in today’s fast-paced technical environment.

1.1 Overview of the Machinery’s Handbook

The Machinery’s Handbook is a renowned reference guide for metalworking‚ engineering‚ and manufacturing‚ published by Industrial Press‚ Inc. It spans 2996 pages in its 31st edition‚ offering detailed coverage of essential principles‚ formulas‚ and standards. With an ISBN of 978-0831141318‚ it is widely regarded as a must-have resource for professionals and students. The handbook has evolved over a century‚ adapting to modern practices while retaining its core focus on practical applications. Available in digital formats like PDF‚ ePub‚ and MOBI‚ it ensures accessibility across devices. Its comprehensive nature makes it an indispensable tool for design‚ manufacturing‚ and related fields‚ providing authoritative guidance for both theoretical and hands-on challenges.

1.2 Importance of the Handbook in Engineering and Manufacturing

The Machinery’s Handbook is a cornerstone in engineering and manufacturing‚ providing essential insights and solutions for professionals and students. It serves as a go-to reference for solving complex problems‚ designing machinery‚ and troubleshooting processes. The handbook’s comprehensive coverage of principles‚ formulas‚ and standards ensures accuracy and efficiency in technical tasks. Its role in education is equally vital‚ aiding students in understanding fundamental concepts and advanced manufacturing practices. By bridging theory and practical applications‚ it supports innovation and precision across industries. The inclusion of modern topics like additive manufacturing and CAD/CAM further cements its importance in contemporary engineering. This versatility makes it indispensable for anyone involved in metalworking‚ design‚ or mechanical engineering‚ ensuring its continued relevance in a rapidly evolving field.

1.3 Evolution of the Handbook Over the Years

Since its inception‚ the Machinery’s Handbook has undergone significant transformations to remain relevant in the ever-changing landscape of engineering and manufacturing. First published over a century ago‚ it has evolved from a basic reference guide into a comprehensive encyclopedia of mechanical engineering. Each edition has incorporated new technologies‚ standards‚ and methodologies‚ ensuring it stays aligned with industry advancements. The addition of digital formats‚ such as PDF‚ has expanded its accessibility‚ allowing users to reference material on PCs and mobile devices. Regular updates‚ including the latest 31st edition‚ reflect the handbook’s commitment to addressing contemporary challenges in fields like additive manufacturing and CAD/CAM. This continuous evolution has solidified its position as a trusted resource for professionals and students worldwide.

Key Features of the Machinery’s Handbook PDF

The Machinery’s Handbook PDF offers comprehensive coverage of metalworking and engineering‚ with detailed tables‚ formulas‚ and standards. Available in digital formats like PDF‚ ePub‚ and MOBI‚ it ensures easy access on PCs and mobile devices. Regular updates‚ including the latest 31st edition‚ provide cutting-edge information‚ making it an indispensable tool for professionals and students in manufacturing and design.

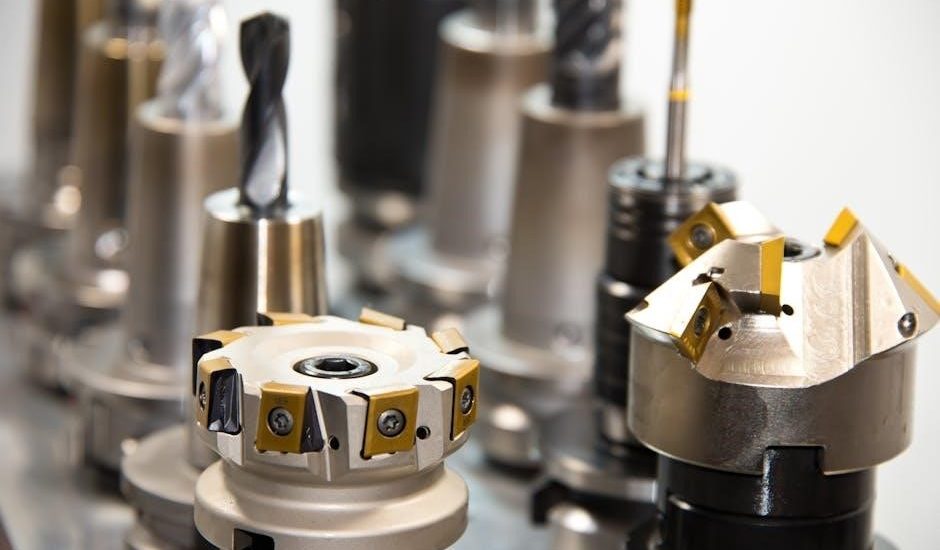

2.1 Comprehensive Coverage of Metalworking and Engineering

The Machinery’s Handbook provides extensive coverage of metalworking and engineering‚ serving as a go-to resource for professionals and students; It includes detailed sections on machining operations‚ tool design‚ and material properties‚ ensuring a thorough understanding of manufacturing processes. The handbook bridges theory and practice‚ offering practical insights into advanced techniques such as additive manufacturing and CAD/CAM. Its comprehensive nature makes it an essential tool for solving complex engineering problems‚ while its clear presentation ensures accessibility for learners at all levels. This breadth of content solidifies its reputation as a cornerstone of technical education and professional development in the field.

2.2 Detailed Tables‚ Formulas‚ and Standards

The Machinery’s Handbook is renowned for its extensive collection of detailed tables‚ formulas‚ and industry standards‚ making it an indispensable tool for engineers and machinists. These tables cover a wide range of topics‚ from fastener dimensions and thread specifications to material properties and machining parameters. The formulas provided are essential for calculations in mechanics‚ strength of materials‚ and gear design‚ ensuring precision and accuracy in engineering tasks. Standards are thoroughly updated to reflect current practices‚ including ISO and ANSI specifications. The handbook’s user-friendly layout allows for quick reference‚ enabling professionals to solve complex problems efficiently. This section is particularly valued for its clarity and comprehensiveness‚ making it a cornerstone for both academic and industrial applications.

2.3 Availability in Digital Formats (PDF‚ ePub‚ MOBI)

The Machinery’s Handbook is now accessible in various digital formats‚ including PDF‚ ePub‚ and MOBI‚ catering to modern professionals’ needs for flexibility and convenience. These formats ensure compatibility across PCs‚ tablets‚ and mobile devices‚ allowing users to access critical information anytime‚ anywhere. The PDF version retains the original layout‚ making it ideal for precise reference‚ while ePub and MOBI offer reflowable text for smaller screens. Digital editions also feature zoom functionality‚ enabling users to magnify complex tables and diagrams for better clarity. This versatility makes the handbook a practical resource for engineers‚ designers‚ and machinists‚ ensuring they can work efficiently in both office and field environments. The digital availability enhances accessibility‚ aligning with the demands of a fast-paced‚ technology-driven industry.

2.4 Regular Updates and New Editions

The Machinery’s Handbook undergoes regular updates to reflect advancements in technology and engineering practices. Each new edition incorporates the latest developments in manufacturing‚ materials‚ and design methodologies‚ ensuring users have access to cutting-edge information. The 31st edition‚ for instance‚ includes expanded coverage of additive manufacturing‚ CAD/CAM‚ and modern metalworking techniques. These updates are driven by feedback from professionals and educators‚ ensuring the handbook remains relevant and authoritative. Contributors like Erik Oberg and Christopher McCauley bring their expertise to refine and expand the content. Regular updates also address emerging trends‚ making the handbook a dynamic and indispensable resource for engineers‚ designers‚ and machinists. This commitment to continuous improvement ensures the handbook stays aligned with industry needs and standards.

Digital Edition of the Machinery’s Handbook

The digital edition of the Machinery’s Handbook offers portability and accessibility in PDF‚ ePub‚ and MOBI formats‚ compatible with PCs and mobile devices for easy reference anywhere.

3.1 Benefits of the Digital Format

The digital format of the Machinery’s Handbook offers unparalleled convenience‚ enabling users to access critical engineering and manufacturing information instantly. Unlike the physical edition‚ the digital version allows for seamless searching‚ bookmarking‚ and quick navigation‚ significantly enhancing productivity. It eliminates the need to carry heavy books‚ making it ideal for fieldwork or remote locations. Additionally‚ the digital format ensures that users always have the most up-to-date information‚ as updates can be easily downloaded. The ability to zoom in on complex diagrams and tables further improves readability‚ especially on mobile devices. Overall‚ the digital format revolutionizes how professionals access and utilize this invaluable resource‚ aligning with the demands of modern engineering and manufacturing environments.

3.2 Compatibility with PCs and Mobile Devices

The digital edition of the Machinery’s Handbook is designed to be fully compatible with both PCs and mobile devices‚ ensuring universal access. Users can seamlessly switch between desktops‚ laptops‚ tablets‚ and smartphones without losing functionality. The PDF format is supported by all major operating systems‚ including Windows‚ macOS‚ iOS‚ and Android‚ making it a versatile tool for engineers and manufacturers on the go. This cross-platform compatibility allows professionals to reference critical data anywhere‚ whether in the office‚ workshop‚ or field. The digital handbook’s responsive design ensures optimal viewing on smaller screens‚ with features like zoom and search functions enhancing usability. This flexibility makes it an indispensable resource for modern professionals who require access to information across multiple devices and environments.

3.3 Zoom and Magnification Features for Complex Data

The digital edition of the Machinery’s Handbook includes advanced zoom and magnification features‚ making it easier to analyze complex data. Tables‚ diagrams‚ and detailed illustrations can be enlarged for clearer viewing‚ ensuring precision when working with intricate designs or specifications. This feature is particularly beneficial for engineers‚ designers‚ and machinists who often work with fine details in blueprints or technical drawings. The ability to magnify content without losing clarity enhances productivity and reduces errors. Additionally‚ the zoom function is intuitive‚ allowing users to quickly focus on specific areas of interest. This capability is a significant advantage of the digital format‚ providing users with the tools they need to handle complex technical information efficiently and effectively.

3.4 Convenience of the Digital Edition

The digital edition of the Machinery’s Handbook offers unparalleled convenience for users. Available in formats like PDF‚ ePub‚ and MOBI‚ it can be accessed on PCs‚ tablets‚ and mobile devices‚ allowing engineers and technicians to reference critical information anytime‚ anywhere. The ability to purchase specific sections or entire editions ensures flexibility‚ catering to diverse needs. Site licenses and custom collections further enhance accessibility for teams or institutions. This digital accessibility not only saves physical storage space but also enables quick searches and updates‚ making it an indispensable tool for modern engineering and manufacturing workflows. The convenience of the digital edition aligns perfectly with the demands of a fast-paced‚ technology-driven industry.

Historical Development of the Machinery’s Handbook

The Machinery’s Handbook began as a reference for machinists in the early 20th century‚ evolving over decades to include modern engineering practices‚ standards‚ and technologies‚ ensuring its relevance and authority in the field.

4.1 Early Editions and Their Significance

The Machinery’s Handbook was first published in the early 20th century‚ initially serving as a pocket guide for machinists and engineers. These early editions laid the foundation for its reputation as a trusted reference‚ focusing on practical applications and essential data. The first edition‚ released in 1914‚ became a cornerstone for professionals in manufacturing and design. Over time‚ each subsequent edition expanded its scope‚ incorporating advancements in technology and engineering practices. By the 29th edition‚ the handbook had evolved into a comprehensive resource‚ offering detailed coverage of metalworking‚ mechanics‚ and modern manufacturing techniques. Its historical significance lies in its ability to adapt to industrial needs‚ making it an indispensable tool for generations of engineers and machinists.

4.2 Contributions of Key Authors and Editors

The Machinery’s Handbook owes its success to the contributions of esteemed authors and editors. Erik Oberg‚ a prominent figure‚ played a pivotal role in shaping early editions‚ ensuring the handbook remained a practical resource. Henry Ryffel later brought his expertise in machinery design‚ expanding the handbook’s technical depth. Christopher McCauley contributed significantly to modernizing content‚ particularly in additive manufacturing and CAD/CAM. These individuals‚ along with others‚ have enriched the handbook with their knowledge‚ keeping it aligned with industrial advancements. Their collaborative efforts have established the handbook as a cornerstone of engineering and manufacturing literature‚ reflecting the evolution of the field over the years. Their dedication has ensured the handbook’s relevance across generations of professionals and students.

4.3 Expansion of Content Over Time

Over the years‚ the Machinery’s Handbook has significantly expanded its content to reflect advancements in engineering and manufacturing. Early editions focused on foundational topics like mechanics and metalworking‚ while later editions incorporated modern practices such as additive manufacturing‚ CAD/CAM‚ and advanced materials. The inclusion of detailed tables‚ formulas‚ and international standards has grown‚ ensuring the handbook remains relevant to global engineering needs. Each new edition restores content from earlier versions‚ offering a comprehensive reference. This evolution has allowed the handbook to adapt to technological progress‚ making it an indispensable resource for both traditional and cutting-edge manufacturing techniques. Its expanded scope ensures it continues to meet the demands of a rapidly changing industry.

Technical Topics Covered in the Handbook

The Machinery’s Handbook covers a wide range of technical topics‚ including mechanics‚ materials‚ manufacturing processes‚ and engineering standards‚ providing essential knowledge for professionals and students in the field.

5.1 Mechanics and Strength of Materials

The Machinery’s Handbook provides in-depth coverage of mechanics and strength of materials‚ essential for understanding structural integrity and material behavior under stress. Detailed sections on stress analysis‚ strain‚ and material properties guide engineers in designing robust components. The handbook includes formulas for calculating bending moments‚ torsion‚ and axial loads‚ along with charts for stress concentrations and fatigue limits. Coverage extends to modern materials like composites and plastics‚ ensuring relevance in contemporary applications. Practical examples and case studies illustrate key concepts‚ making it a valuable resource for both academic and industrial settings. This section equips users with the tools to optimize material selection and ensure component reliability in diverse engineering scenarios. The content is supported by clear diagrams and tables‚ enhancing comprehension and application.

5.2 Additive Manufacturing and Modern Practices

The Machinery’s Handbook dedicates extensive coverage to additive manufacturing‚ exploring its principles‚ applications‚ and integration with modern engineering practices. It delves into technologies like 3D printing‚ detailing processes such as fused deposition modeling (FDM) and selective laser sintering (SLS). The handbook provides insights into designing for additive manufacturing (DFAM)‚ highlighting how it differs from traditional subtractive methods. Topics include material considerations‚ post-processing techniques‚ and the role of CAD/CAM software in creating complex geometries. Environmental impacts and cost efficiencies are also addressed‚ emphasizing sustainability in production. This section bridges theory and practice‚ offering practical guidance for engineers and designers looking to leverage additive manufacturing for innovation and efficiency in today’s industrial landscape. The content is enriched with real-world examples and updated methodologies.

The Machinery’s Handbook provides an in-depth exploration of threads‚ fasteners‚ and gearing‚ essential components in mechanical design and manufacturing. It covers various thread types‚ including ISO and Whitworth standards‚ with detailed tables for pitch diameters and thread angles. Fasteners are thoroughly examined‚ from bolts and screws to nuts and washers‚ emphasizing torque specifications and material strength. The section on gearing includes spur‚ helical‚ and bevel gears‚ with formulas for calculating tooth proportions and gear ratios. Practical applications and installation guidelines are also provided‚ ensuring engineers and machinists can design and assemble components with precision. This comprehensive coverage ensures the handbook remains a vital resource for anyone working with mechanical systems‚ offering clear‚ concise‚ and actionable information. Updated standards and practices are highlighted throughout. The Machinery’s Handbook extensively covers casting and metalworking techniques‚ providing detailed insights into various manufacturing processes. It explores methods such as sand casting‚ investment casting‚ and die casting‚ along with material selection and quality control measures. The handbook also delves into forging‚ stamping‚ and extrusion processes‚ offering practical guidance on achieving precise and durable components. Metalworking techniques‚ including heat treatment‚ machining‚ and surface finishing‚ are thoroughly explained. Standards and best practices are emphasized‚ ensuring compliance with industry requirements. The section also addresses modern advancements in casting technologies‚ such as additive manufacturing‚ and their integration with traditional methods. This comprehensive coverage makes it an invaluable resource for engineers‚ machinists‚ and manufacturers seeking to optimize their production processes and product quality. The Machinery’s Handbook serves as an essential guide for manufacturing and design processes‚ aiding engineers and machinists in solving technical challenges‚ optimizing workflows‚ and ensuring precision in production. The Machinery’s Handbook is indispensable in manufacturing and design‚ offering detailed guidance for machining operations‚ tool design‚ and quality control. Its comprehensive coverage of metalworking techniques‚ including additive manufacturing and modern casting methods‚ ensures precise and efficient production processes. Engineers and machinists rely on its formulas and standards to solve technical challenges‚ optimize workflows‚ and maintain high-quality outputs. The handbook’s practical applications extend to CAD/CAM integration‚ material selection‚ and troubleshooting‚ making it a cornerstone for both traditional and advanced manufacturing practices. With its wealth of information‚ it streamlines design processes‚ enhances productivity‚ and supports the creation of innovative solutions in the industry. The digital edition further enhances accessibility‚ allowing seamless integration into modern workflows. The Machinery’s Handbook serves as a vital educational resource for engineering students and professionals‚ offering a foundation in metalworking‚ design‚ and manufacturing. Widely used in academic institutions‚ it provides clear explanations of fundamental principles‚ making complex concepts accessible. The handbook’s detailed tables‚ formulas‚ and standards are essential for coursework and practical training. Its coverage of topics like mechanics‚ materials‚ and additive manufacturing prepares students for real-world challenges. The digital edition enhances learning by allowing easy access to information and zoom features for detailed analysis. It bridges the gap between theory and practice‚ equipping future engineers with the knowledge and skills needed for successful careers in the field. This makes it an indispensable tool for engineering education and professional development. The Machinery’s Handbook is an essential resource for tool and fixture design‚ providing detailed specifications for threads‚ fasteners‚ and gearing. Its comprehensive tables and formulas enable precise calculations for tooling components‚ ensuring accuracy and efficiency. The handbook’s coverage of metalworking techniques and standards directly supports the design of custom tools and fixtures. The digital edition’s zoom feature allows designers to examine complex diagrams and blueprints in detail‚ facilitating the creation of intricate tooling systems. By offering practical‚ real-world applications‚ the handbook serves as a cornerstone for engineers and machinists involved in tool design‚ helping them adhere to industry standards and best practices. This ensures the development of reliable‚ high-performance tools and fixtures for various manufacturing needs. The Machinery’s Handbook is supported by companion volumes and additional materials‚ including a guide to using tables and formulas. These resources enhance its utility‚ offering detailed explanations and practical examples to complement the handbook’s content. The guide provides handy links to digital edition pages‚ enabling users to master essential principles effectively. Supplementary resources ensure the handbook remains a complete and indispensable reference for engineers and machinists. The Guide to the Use of Tables and Formulas is a supplementary resource designed to enhance the usability of the Machinery’s Handbook. This guide provides detailed explanations and practical examples to help users effectively navigate and apply the extensive tables‚ formulas‚ and standards contained in the handbook. It serves as a bridge between theoretical knowledge and practical application‚ ensuring that engineers‚ designers‚ and machinists can fully leverage the handbook’s content. The guide is particularly useful for interpreting complex data‚ such as thread dimensions‚ gear specifications‚ and material properties. By offering clear instructions and cross-references‚ it simplifies the process of locating and utilizing specific information‚ making it an indispensable companion for both experienced professionals and students. In addition to the main handbook‚ companion volumes and supplementary materials are available to further enhance its utility. These include specialized guides‚ such as the Pocket Companion‚ which provides condensed yet essential information for quick reference. Additional materials‚ like cross-referenced digital links‚ ensure seamless navigation between the handbook and its supplementary resources. These companions are designed to cater to specific needs‚ offering in-depth coverage of niche topics while maintaining consistency with the core content. They are particularly useful for professionals seeking specialized knowledge or students requiring additional study aids. Together‚ these resources create a comprehensive ecosystem that supports diverse engineering and manufacturing challenges‚ ensuring users have access to a wealth of knowledge tailored to their requirements. The Machinery’s Handbook PDF is widely available on online platforms like OZON and engineeringbookspdf.com. It can be purchased in various formats with flexible pricing options. The Machinery’s Handbook PDF is accessible on various online platforms‚ including OZON and engineeringbookspdf.com; These platforms offer quick and convenient access to the digital edition‚ allowing users to purchase and download the handbook with ease. Additionally‚ the PDF is available through Industrial Press‚ Inc.’s official website‚ ensuring authenticity and quality. With the rise of digital resources‚ the handbook has become more accessible to engineers‚ designers‚ and students globally. Its availability in multiple formats‚ including PDF‚ ePub‚ and MOBI‚ ensures compatibility with PCs‚ tablets‚ and mobile devices‚ making it a versatile tool for modern professionals. The digital edition is regularly updated‚ providing users with the latest advancements in engineering and manufacturing. The Machinery’s Handbook PDF is available for purchase through Industrial Press‚ Inc.‚ and other online retailers like OZON. Pricing varies depending on the format and edition‚ with digital versions generally more affordable than hardcover editions. The 31st edition‚ for instance‚ is priced competitively‚ offering excellent value for its comprehensive content. Additionally‚ Industrial Press offers site licenses and custom eBook collections‚ providing flexible purchasing options for institutions and businesses. Discounts are often available for bulk orders‚ making it accessible for educational and industrial use. The handbook’s pricing reflects its status as a premium resource‚ ensuring it remains a cost-effective investment for professionals and students seeking detailed engineering and manufacturing insights. The Machinery’s Handbook will continue to evolve‚ incorporating advancements in manufacturing‚ additive technologies‚ and digital tools. Future editions will likely expand coverage of emerging engineering practices and innovations‚ ensuring its relevance for decades to come. Future editions of the Machinery’s Handbook are expected to integrate advancements in additive manufacturing‚ AI-driven design tools‚ and sustainable engineering practices. The handbook will likely expand its coverage of emerging technologies‚ such as Industry 4.0 and smart manufacturing‚ to cater to modern industrial demands. Enhanced digital features‚ including interactive 3D models and real-time updates‚ may be introduced to improve user experience. Additionally‚ the inclusion of more international standards and codes will ensure global relevance. These updates aim to maintain the handbook’s status as a leading resource for engineers‚ designers‚ and manufacturers‚ adapting to the rapid evolution of the field while preserving its core practicality and comprehensiveness.5.3 Threads‚ Fasteners‚ and Gearing

5.4 Casting and Metalworking Techniques

Practical Applications of the Machinery’s Handbook

6.1 Use in Manufacturing and Design Processes

6.2 Role in Engineering Education and Training

6.3 Application in Tool and Fixture Design

Supplementary Resources and Guides

7.1 Guide to the Use of Tables and Formulas

7.2 Companion Volumes and Additional Materials

Purchasing and Accessing the Machinery’s Handbook PDF

8.1 Availability on Online Platforms

8.2 Purchase Options and Pricing

The Future of the Machinery’s Handbook

9.1 Anticipated Updates and Innovations